Integrated at Work (IAW) delivered a complete glass wall system with doors and sliding doors for the University’s newly constructed College of Engineering. The 190,000 SF building is the largest construction project in the University’s history. The single, six-floor building replaces five older buildings on the University’s engineering campus.

Creating light-filled expanses of open space for the state-of-the-art classrooms and laboratories was key. To help achieve this, IAW installed a 12’0” high glass wall in an area on the building’s first floor.

Integrated at Work (IAW) installed both a sound masking system (38,200 SF) and a raised flooring system (6,100 SF) as part of Cape Cod 5’s new banking center and headquarters built to accommodate 300+ employees.

After reviewing the space and speech privacy requirements, IAW provided a layout optimizing the correct level of ambient sound for space. Additionally, IAW incorporated a paging system into the sound masking system to provide cost savings to the client versus providing each system separately.

Cape Cod 5’s project requirements included a need for flexibility and accessible power and data locations in the large assembly room. The TecCrete raised flooring offered a great solution that offered a solid walking sensation along with the ultimate flexibility.

Implementing green design and building features were a priority. Cape Cod 5’s project achieved LEED Gold certification.

Learn more about this great project.

Integrated at Work delivered a raised access flooring system as the first phase of Decipera Pharmaceuticals’ expansion project. The Tecrete raised floor system elevated a separate workspace in the center of the office to allow for increased privacy. IAW specified 7,800 SF of the TecCrete 1250 panel system which provides the rigidity and stability to meet the needs of this demanding and flexible workspace.

IAW worked simultaneously under a fast-track schedule with the trades and contractors on site. Though the site was not fully built-out, IAW successfully prepared the railing production and flooring installation. Since the construction schedule dictated installation in phases, IAW was able to visualize the remaining installation by calculating and analyzing exactly how much material was needed. Additionally, our team installed the RAF and railing system without affecting furniture installation.

A unique aspect of this project was a back-lit through integrated as part of the raised floor system. IAW coordinated this detail with the architect, general contractor, and lighting contractor to achieve the desired lighting effect

Integrated at Work (IAW) delivered multiple projects for a global corporation’s R&D and manufacturing site in Connecticut. The most recent installation included a single-glazed Haworth Enclosed Frameless Glass (EFG) office and conference room front system as part of a phased renovation project. IAW coordinated with the project architect to create a unique custom booth solution to satisfy the client’s needs. Using Haworth EFG in conjunction with the Haworth Enclose stack-on wall system provided privacy and divided space between each workstation and created a great area to collaborate.

IAW successfully delivered and installed the project during the COVID-19 pandemic. The team was able to quickly adapt the project schedule despite manufacturing uncertainty, providing necessary site preparations and guidelines for on-site safety of the installation crew, and making overall accommodations for unforeseen schedule adjustments. IAW proudly continues to work with the client on future planned projects and campus enhancements.

Integrated at Work utilized its expansive product offering and industry experience to deliver a complete exterior and interior glazing package for a software company headquarters space. The ability to offer both exterior building envelope solutions, exterior paver solutions, along with interior demountable glazing systems under one contract set us apart. The benefit to the client was utilizing our team as the one point of contact which resulted in a seamlessly run project.

Integrated at Work (IAW) effectively executed the interior glazing package as well as the assembly and installation of the exterior curtain wall system as part of a phased construction renovation project at Siemens Healthineers’ Laboratory Diagnostics campus.

IAW aligned, attached, and sealed the curtain wall to an existing system. Two different metal panel systems supplied by others terminated at the newly installed curtain wall. Our team worked with the panel subcontractor to coordinate the terminations ensuring that a seamless air and vapor barrier could be achieved.

Integrated at Work (IAW) completed a complex project for Akamai’s new global headquarters in Cambridge, Massachusetts. IAW installed 12,000 LF of demountable walls and a full interior glass and glazing package.

Throughout the project, detailed coordination ensured the final build-out is fully consistent with the design aspirations of the project, as well as all targets for sustainability (LEED and WELL).

Integrated at Work (IAW) recently completed a high-end, customized demountable walls project with Columbia Construction for Great Hill Partners (GHP). Located on the 29th Floor of the Hancock Building, GHP is a private equity firm that embodies the core values of integrity, teamwork, accountability, attitude, meritocracy, and a desire to win. Architect Gensler sought to incorporate these values in an interior design that distinctly reflects the GHP culture while raising the bar for industry expectations.

IAW proposed the Muraflex MIMO demountable wall system to complement Gensler’s theme of elegant and edgy. MIMO is the most slender and sophisticated demountable glass office wall solution in the IAW portfolio. Modern and minimal, it maximizes natural light while fostering dynamic and transparent teaming. True to its demountable nature the MIMO system is highly adaptable and can be easily reconfigured to meet the demands of Great Hill Partners’ long-term business needs. Further, as the walls are not affixed to drywall, future changes can be completed without the time and expense of outsourcing a demo crew.

Unique to this project, the IAW team elevated the capabilities of the MIMO system by customizing it for the GHP entryway. A challenging task that drew upon years of interior glazing expertise while expanding upon knowledge of the Muraflex system and Maglocks security hardware. We are proud to say that the results speak for themselves – what a way to make an entrance!

But don’t just take our word for it – even the elevator operator at the Hancock Building agrees that Great Hill Partners is the, “nicest floor in the building.”

This project was an interesting take on using demountable systems to create a refined, modern space that clearly represents the client. An aggressive schedule, with a lot of changes, required major coordination efforts with other trades but we stayed one step ahead, the entire way.

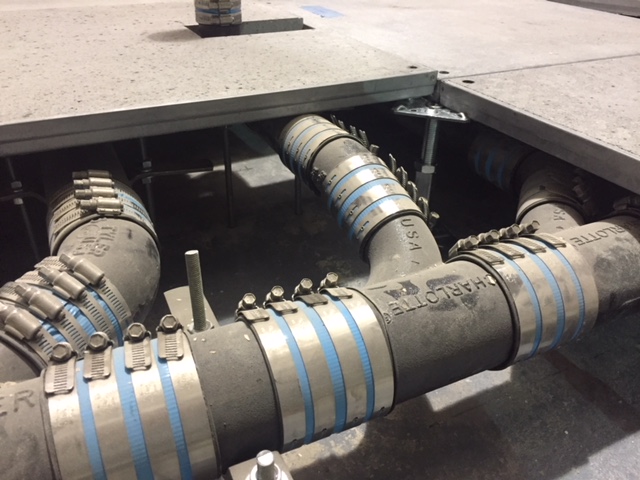

Integrated at Work (IAW) recently completed a unique and dynamic installation project with Columbia Construction using TecCrete raised flooring. The project goal was to redevelop an uninhabitable basement space and retro-fit the new space with bathrooms, showers, and employee bike storage for the new occupant – a high-profile, online retail giant.

Located in a building originally developed in 1902 as part of the NECCO factory complex in Fort Point, Boston, the project site proved challenging from the get-go. General Manager, David Atwood, says that the existing conditions resembled a skateboarding park with extreme slopes, slab buckles, and overall severe unlevelness.

Atwood himself had never seen a space quite like this but assured the team that TecCrete raised flooring was the right solution for the job. The pedestal and concrete paneling system of raised flooring absorbs extreme sub-floor conditions and has the flexibility necessary to achieve laser-levelness. Not only does it allow for variable height adjustments for existing conditions and new plumbing, but it also offers unique characteristics that do not exist in new construction. Uniformly flat and bone-dry, TecCrete installs ready for tile adherence.

“This crew of installers and project managers was very collaborative and willing to help solve any issues that arose. The final outcome was a great success!”

We use cookies to improve your experience on our site. By using our site, you consent to cookies.

Websites store cookies to enhance functionality and personalise your experience. You can manage your preferences, but blocking some cookies may impact site performance and services.

Essential cookies enable basic functions and are necessary for the proper function of the website.

These cookies are needed for adding comments on this website.

Statistics cookies collect information anonymously. This information helps us understand how visitors use our website.

Google Analytics is a powerful tool that tracks and analyzes website traffic for informed marketing decisions.

Service URL: policies.google.com

You can find more information in our Cookie Policy and .